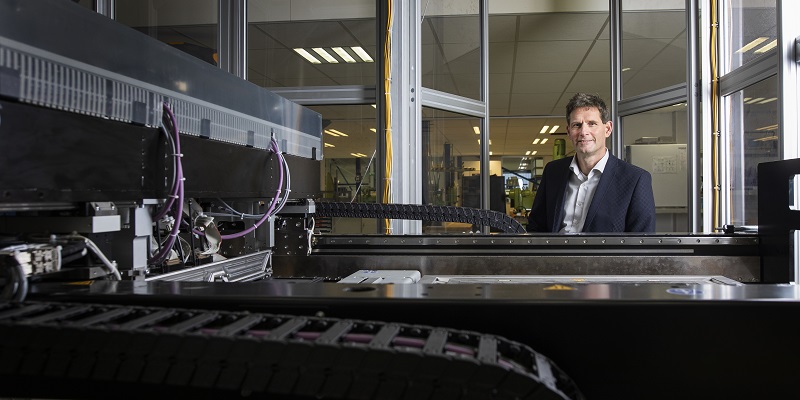

Patrick Strating - NTS

Despite competition from China and the US, the Netherlands continues to play a major role in the world of high tech. Patrick Strating of NTS believes it starts with high-tech companies that have close ties to top-notch technical universities and continues with ambitious workers that thrive on life-long learning through training. NTS organizes the Consultative selling training from time to time.

Roughly five years ago, NTS started on a new mission: to become a leading supplier of machine equipment for the world’s top OEMs. In order to achieve this, the Eindhoven-based company set out on a series of acquisitions to bring in all the necessary expertise and abilities to build high-precision parts, equipment and machines. “Our aim is to function in the state-of-the-art domain and beyond, where technology boundaries are pushed,” explains NTS’ Technology Manager of Development & Engineering, Patrick Strating.

With this ambitious plan, however, comes a unique set of challenges to overcome. As NTS grew, it was composed out of a number of individual satellite locations, each with a different focus and expertise – which can be difficult when trying to build a cohesive team and vision.

“Ours is really a story of integration. NTS has been built up from separate entities. They were suppliers of frames and sheet metal, suppliers of precision metal parts and several engineering units of different kinds,” describes Strating. “To become an integrated equipment supplier, you need to master the complexity of the entire development and manufacturing chain. That requires much more than just skilled people executing supply chain work or doing machining on metal parts; there’s a need for employees who are fully technology-savvy and context-aware, and who can work with complexity while maintaining an eye on what our customer wants.”

Photo by Vincent van den Hoogen.

Proactive

Realizing the task at hand, NTS adopted a two-step solution. First, educate its workers from both the company and customer perspective of the new reality of being a first-tier supplier of specialized systems. Second, look to the labor market to find emerging talent with modern skills. “To understand the complexity of the machines, we needed a gradual buildup of both training of existing people, as well as attracting new people with more advanced multidisciplinary skills and a passion for life-long learning,” highlights Strating.

“At NTS, we offer a robust employee training program with individual coaching, technical mentorships and training. In addition, we have programs to stimulate craftsmanship at our manufacturing sites. We see it as a necessity to offer extensive training because it gives our employees a sort of basis or foundation in technical areas. But our true hope is that it also inspires them to continue broadening their scope, continue learning and to keep moving with our customers. We work with challenging companies like ASML, Philips and Zeiss, so it’s imperative that we’re keeping up to speed with them and even helping guide them with our expertise.”

To establish and preserve their expert knowledge, the workers at NTS often attend technical trainings in optics, mechatronics and systems development. Perhaps somewhat surprising, however, is the benefit the company sees by emphasizing social trainings like soft skills and sales. “Take the consultative selling for technology professionals training. That’s really about understanding your product and how it relates to the customer’s needs and values,” Strating illustrates.

“It’s been a part of NTS’ migration. Five years ago, as a supplier, we were more in a reactive mode. A customer would come to us with an issue and we would spend a lot of time in discussion to fully understand what was needed. Now, we can be more proactive. We go to work with our customers and really trying to elevate knowledge and innovate alongside them. Having a sound systems engineering basis and speaking the same language as our customers allow us to bring our manufacturing expertise to the table. In the end, our customers want critical equipment to be delivered, and our broad-based yet detailed manufacturing expertise is our key asset.”

Would you say that training is a tool for staying ahead of your customers?

“Not necessarily. For some trainings, that might be true. But for the more conventional courses, like mechatronics or systems engineering, what’s really needed is to establish a common base. Our engineers need to speak the same type of language as our customers,” expresses Strating. “You find that there’s this sort of specialized lingo and common approaches to issues in our industry, and this is really where the value is in technical training. But this doesn’t just serve NTS, it serves the entire high tech ecosystem of the region.”

Competitive

Strating believes the Dutch way of working is a real point of differentiation compared to other regional ecosystems. To him, the Netherlands and Belgium are very connected, communicative, competitive and collegial. “More or less, we depend on one another because we all supply each other. Of course, we can be competitive, but in the end, we’re all working with the same customers and they benefit from the cooperation and alignment of their suppliers,” says Strating. “Dutch companies are continually exchanging ideas, best practices and personnel. We find that if we continue to do things better if we share a common language in terms of technology and engineering methods, and if we have common people that demonstrate agility to address gaps within our ecosystem, it helps us compete with larger-market supply chains in China and the US.”

'High Tech Institute has strong roots within these universities and is able to incorporate modern technology approaches in their high-quality, professional and technical trainings.'

In describing how the culture of Dutch high tech was built, Strating points to the role of the technical schools. “I think the three technical universities form the high tech basis in the Netherlands. They’re responsible for shaping our future innovators and providing them with the common building blocks to succeed in this industry. I think as companies, it’s important that we continue to recognize that, but also work with these institutions in various forms of industrial cooperation,” voices Strating. “That’s one reason we turn to High Tech Institute for training. They have strong roots within these universities and are able to incorporate modern technology approaches in their high-quality, professional and technical trainings. That’s an important criterion for us.”

Flexible

Looking ahead to the next five years, NTS’ ambition is to use its expertise to lead the way in combining high-tech engineering with manufacturing. This will require highly trained workers that can understand not only the customer’s needs and challenges, but also have the ability to go through the engineering cycle and connect customers with their roadmap, all the way to the end-user.

“We want to bring together the worlds of customers, technical people and high-precision equipment. This will require incredibly talented and creative workers that are willing to really stretch technology to bridge the gaps. Those people are not so easily found; they have to be developed and that’s what we believe training and coaching help us achieve,” states Strating. “Training courses are important pieces of the puzzle. They’re instrumental in creating those flexible people that have a technical mindset and want to make a difference by understanding and optimizing this entire chain. That’s where we want to excel. That’s how we will grow the NTS market position as we look to be the best at playing this complicated global game.”

This article is written by Collin Arocho, tech editor of Bits&Chips.

Recommendation by former participants

By the end of the training participants are asked to fill out an evaluation form. To the question: 'Would you recommend this training to others?' they responded with a 9.1 out of 10.