Lectures supported by practical demonstrations and quizes. Course notes.

While EMC requirements are often defined by electronic engineers, their successful implementation depends heavily on mechatronic and mechanical design choices—especially in the areas of cabling, shielding, and enclosure architecture. This course empowers mechanical and mechatronic system engineers with the essential knowledge to recognize EMC risks and apply design techniques that prevent costly compliance failures.

This training stands out due to:

- it being tailored for mechanical design: focus on EMC at cable, connector and enclosure level

- bridging disciplines: enhances collaboration between mechanical and electronic engineers

- immediately applicable: practical techniques for first-time EMC success

- interactive format: clear explanations, live demos and quizzes

- flexible setup: in-company course with optional custom third session

By strengthening the collaboration between mechanical and electronic disciplines, this training ensures products meet EMC standards the first time—minimizing redesigns, delays, and unnecessary costs.

This training is available for in-company sessions that can be customized to fit your product architecture or development process.

Objective

After completing the training, the participant will:

- Understand the basic principles of EMC and typical mechanical causes of EMC problems;

- Be able to interpret and implement EMC design requirements;

- Communicate effectively with electronic engineers on EMC topics;

- Apply practical EMC techniques to cables, connectors, filters, enclosures, and grounding;

- Reduce the risk of non-compliance and avoid expensive late-stage design modifications.

Target audience

This course is designed for:

- Mechatronic and mechanical engineers

- System architects

- Project leaders

- Quality engineers

Prerequisites: Bachelor or Master of Science in mechanics, mechatronics, electronics or physics.

Program

Afternoon 1 – EMC Foundations & Cables

· What is EMC? (source – coupling – victim model)

· Legal requirements and standards (emission and immunity)

· EMC-focused design strategy during product development

· EMC at cables and connector level:

o Basic principles (wavelengths, antenna behavior)

o Cable characteristics and classifications

o Cable mounting and routing

o Connector shielding

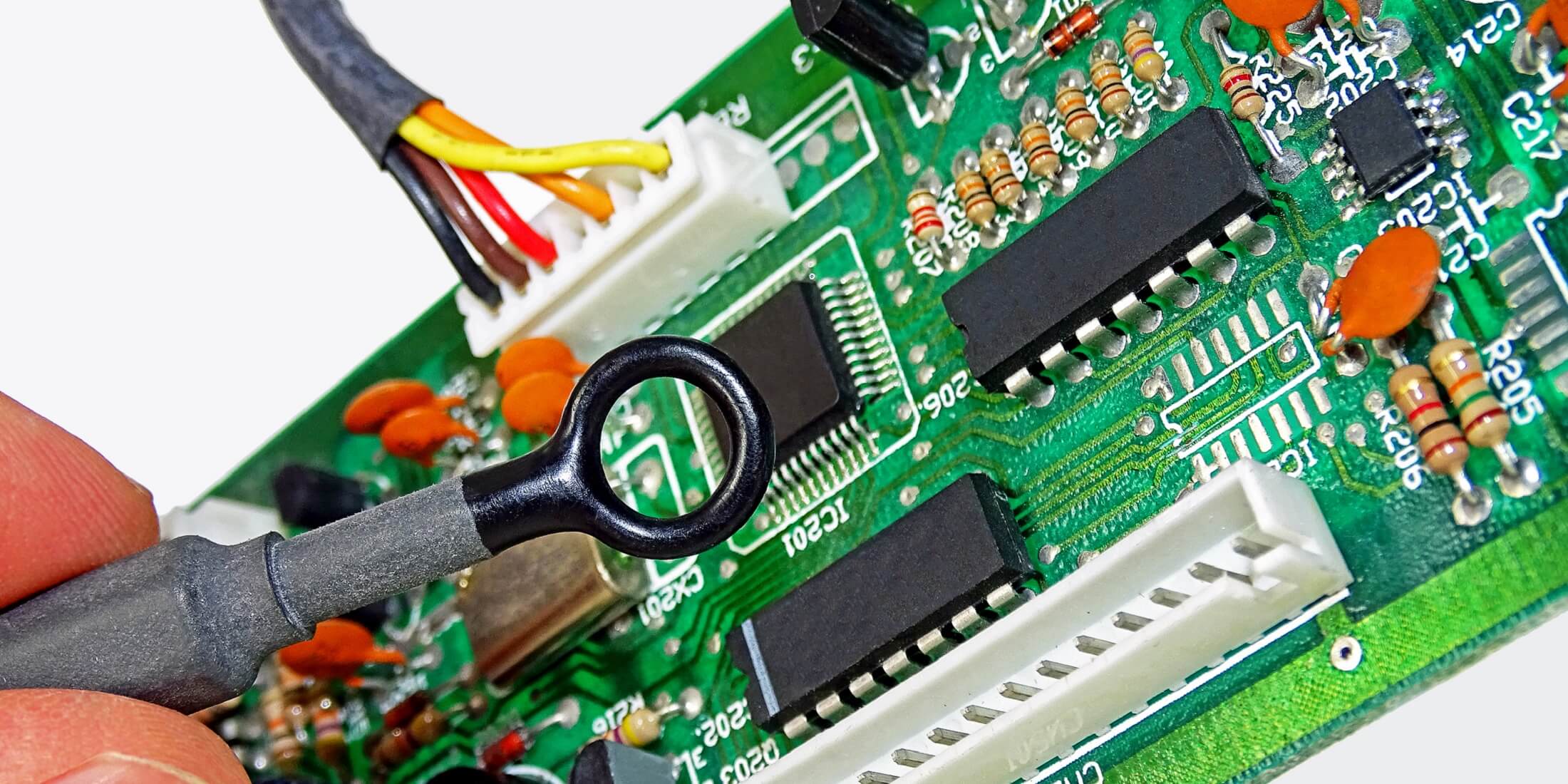

· Live demonstrations and knowledge quiz

Afternoon 2 – Enclosures & Shielding

· Shielding techniques for electric and magnetic fields

· Material choice, effect of seams, and holes

· Mechanical architecture

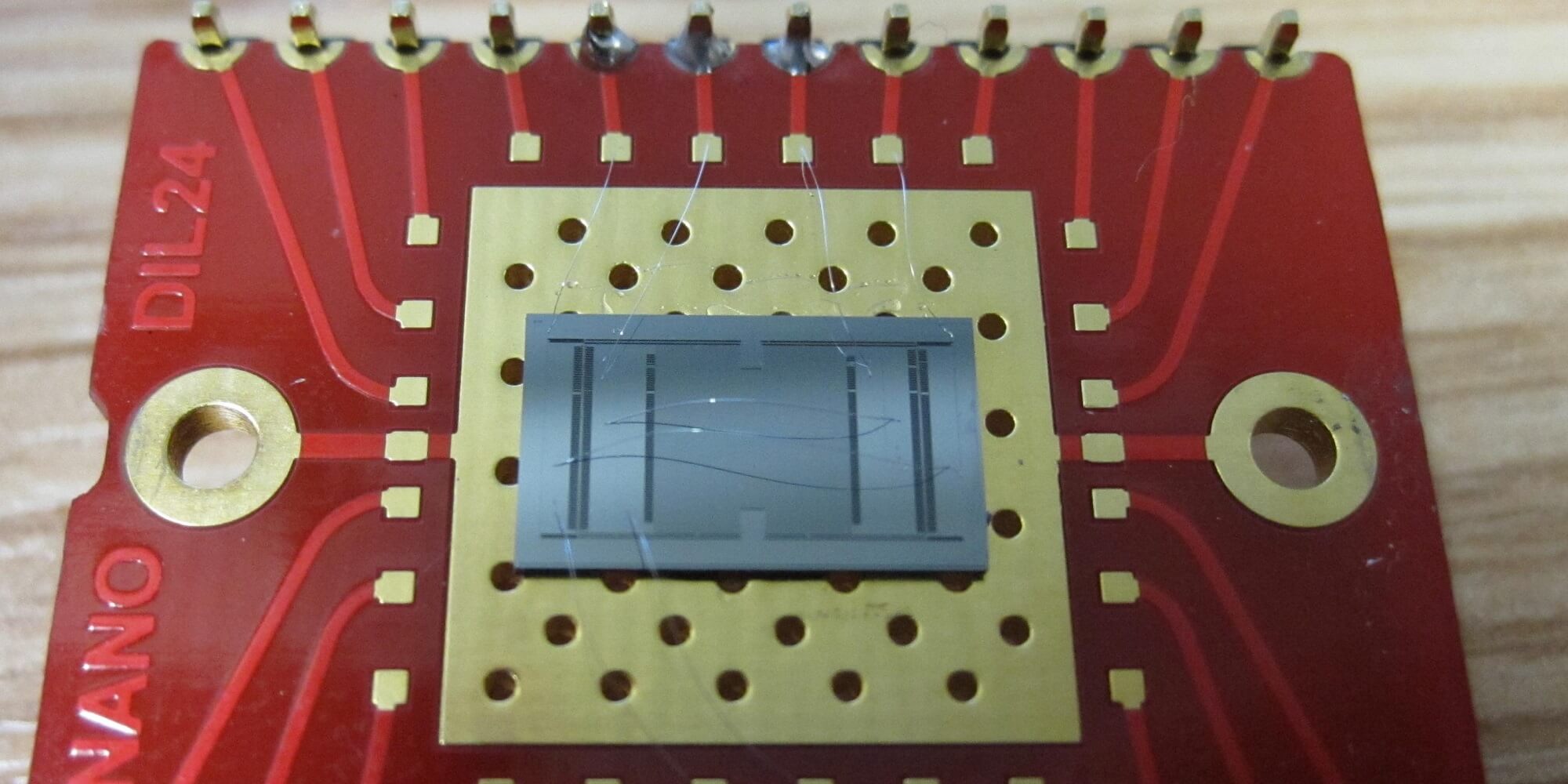

· Filter mounting, grounding concepts, PCB-level shielding

· Live demonstrations and interactive quiz

· Wrap-up and certification

Optional Afternoon 3 – Application Focus (Customized)

E.g. review of participants' own designs/devices

Methods

Certification

Participants receive a High Tech Institute course certificaten for attending this training.

Remarks from participants