Hans Vermeulen & Kees Verbaan - Trainers

Passive damping has been a standard tool for civil engineers and architects for quite some time. Mechanical engineers, however, designing for micron accuracy typically tried to avoid the use of damping. Now the high tech world has entered the domain of sub-nanometer precision, mechanical engineers are more and more discovering that passive damping is an effective medicine for contemporary precision ailments.

In recent years, passive damping is becoming more and more a standard tool for precision engineers. It is not a coincidence that the five-day training course Design Principles for Precision Engineering devotes a whole day to this subject. Due to the increasing importance of passive damping for systems with subnanometer position requirements, High Tech Institute-partner Mechatronics Academy, has developed a special training course in this topic. Top experts Hans Vermeulen and Kees Verbaan teach this new course Passive damping for high tech systems.

Hans Vermeulen first came into contact with passive damping at Philips CFT in the late nineties. Since mid-2000, he works at ASML, where this technology has meanwhile been implemented in various sub-systems to achieve sub-nanometer level precision. He is also a part-time professor at the TU Eindhoven for one day a week. Unhindered by the daily hectics in Veldhoven, Vermeulen is able to focus, among others, on passive damping. The fact that his lectures in this field started several years ago shows that passive damping is very much in the spotlight.

Hans Vermeulen informs that ASML is increasingly using passive damping to achieve sub-nanometer precision.

Colleague-trainer Kees Verbaan received his doctorate in robust mass dampers for motion stages in 2015. He works for the NTS Group, a first-tier supplier for high tech machine design. In his role as system architect, Verbaan sees passive damping technology as becoming well established in many high-end companies.

System architect Kees Verbaan who obtained his doctorate in robust mass dampers, now sees his professional field become well established.

In the world of gross dimensions (centimetres instead of nanometres), passive damping is encountered everywhere. Put your finger on a vibrating tuning fork or nail a large rug to the wall and you readily apply passive dampinging. The automobile industry frequently applies it to car doors. A layer of anti-banging film renders a good sound experience. When you close the door, you don’t hear the sheet metal annoyingly resonate: the damping layer provides the gentle sound that we associate with quality. The energy doesn’t stay in the material as a continuous vibration, but is transferred into heat via a layer of bitumen on the inside of the door. A rather extreme example of a passive damping design is to be found in Taipei 101, the tallest building in the eponymous Taiwanese capital. Because earthquakes and typhoons appear quite frequently, the 101-storey building is equipped with a tuned mass damper, a huge spherical mass of more than eight hundred tons that hangs at the top of the building on four ropes and is provided with large viscous dampers. In the event of vibrations caused by earthquakes or severe storms, the sphere moves out of phase, absorbing a large part of the building’s kinetic energy.’Similar techniques are also now entering high tech,’ Hans Vermeulen says. ‘In recent years, damping layers – so-called constrained layers – have been applied in high-precision stages and tuned mass dampers are being used to suppress disturbing vibrations at specific frequencies to increase the accuracy of the entire system.’

In high tech mechanical engineering, the application passive damping has been avoided and worked around for a long time. This is mainly due to the fact that designers were able to reach their goals (and often still can) with the traditional approach of using relatively stiff structures in metal or ceramics and metal springs to get predictable behaviour.

Plastics, rubber and composites

Although the use of plastics, rubber material and composites can significantly reduce unwanted vibrations, the application has never been that popular, because the hysteretic behaviour of these materials potentially makes precision systems unpredictable. Another reason is that, for a long time, analytical tools such as finite element analysis and the necessary computers didn’t have sufficient computing power to calculate the complex behaviour necessary to properly predict the influence of passive damping in structures made from exotic materials. In recent years, however, things have changed.

It may be a truism, but it’s still very true: in the world of high tech systems, the demands for precision are constantly increasing. Semiconductor manufacturers want lithographic machines that are able to make patterns in a reliable way at sub-nanometer level precision. Biotechnologists need microscopes that allow for imaging DNA structures at atomic level and medical professionals jump rely on diagnostic equipment with, if possible, molecular resolution. In all sectors, demands are rising, in such a way that mechanical designers and architects can no longer rely on their standard toolset.

''In the traditional toolset of a design engineer there used to be three drawers of tools. Now it appears there are six..'

It appears that passive damping can make a very significant contribution here. The approach has proven effectiveness, also in the high tech equipment. ‘The nice thing about damping is that a whole new box of tricks is being used,’ Verbaan says. ‘Precision engineers really benefit from a few additional pieces on their chessboard. I like that, because in a manufacturer’s traditional toolkit, there were only three full drawers. Now it turns out that there are three more and they are full of new types of tools that he didn’t use before.’ He underlines that damping is an extension of the solution space, not a replacement. ‘If you don’t master traditional design, the additions will not bring you much.’

‘When requirement were less demanding, designers were used to the predictable solution space consisting of masses and springs,’ Vermeulen says. ‘In traditional design you have to deal with linear relationships, such as relationships between force and position or stress and strain. To limit the negative effect of amplifications at resonance, designers make sure that the natural frequencies in the system are sufficiently high enough. That translates into light and rigid designs, using low mass solutions and highly stiff materials and geometries. ‘

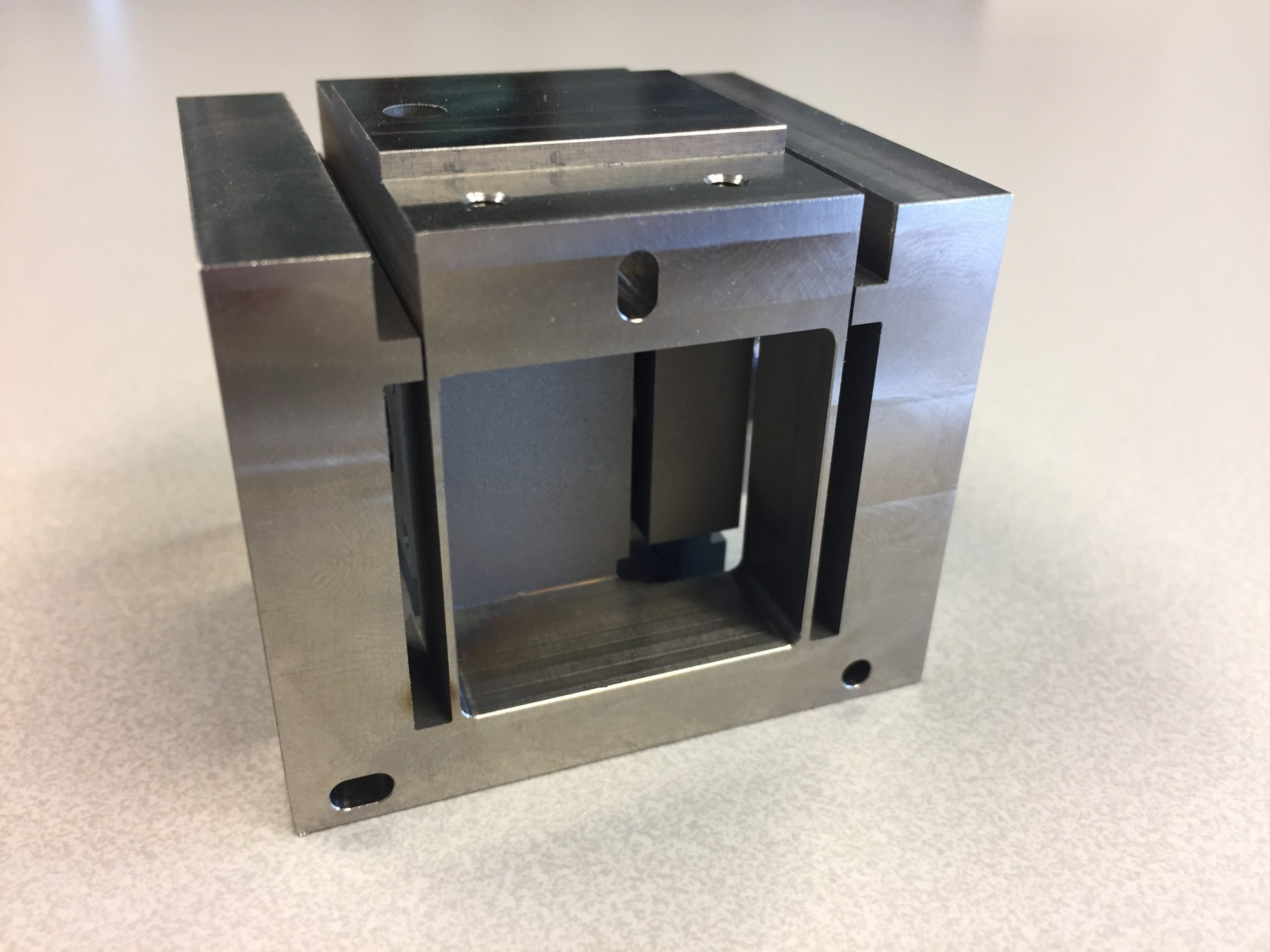

Monolithic leaf spring

Hooke’s law states a linear relationship between force and position or stress and strain for linear elastic materials. This means that an elastic material returns exactly to its original position, which is nice, because as long as you know the forces that act on the system, you can accurately predict the position. Take the example of a monolithic leaf spring, a solid block of metal that has been processed with holes and slots into a mechanism based on masses and springs. Such a structure exhibits reproducible linear behaviour, free from hysteresis. From control perspective, however, this approach might create a problems in case higher precision is required.

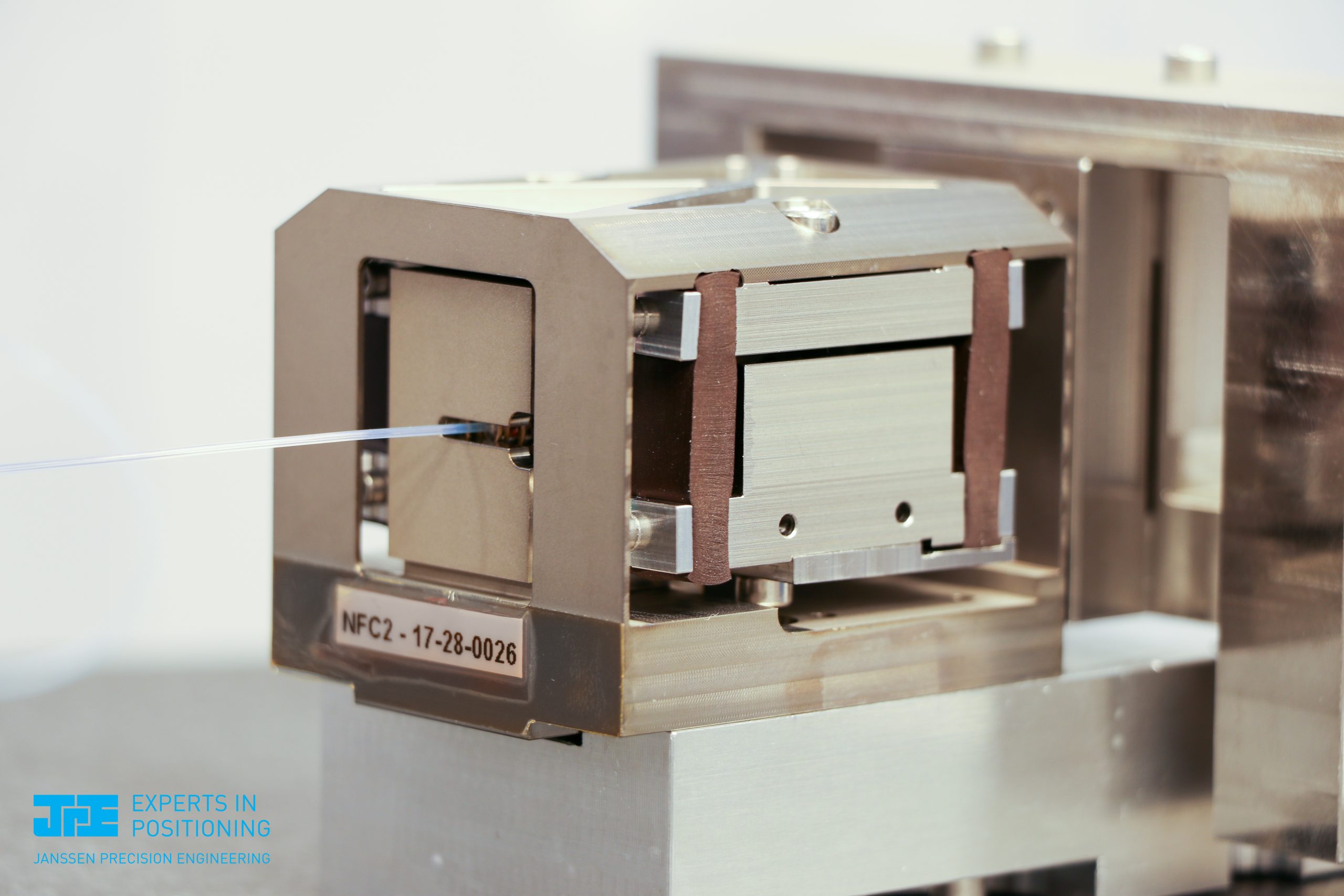

Typical construction with integraed tuned mass damping. Photo: Janssen Precision Engineering.

Example of a monolithic leaf spring. A solid block of metal is processed with holes and slots into a mechanism based on masses and spring. Such a structure exhibits reproducible linear behaviour but has the disadvantage that it ‘sounds like a clock.’

In this type of design, the control system suffer from long lasting vibrations. Resonances might be excited by forces within the system itself, such as imposed motion profiles, but also due to external influences, for example floor vibrations or air displacement. Without damping, these vibrations remain in the system for a long time. The vibration cannot get rid of the vibrational energy.

Mechanical engineers tend to say: ‘it sounds like a clock,’ and in this case this is not a positive observation. High frequency resonances are generally difficult to get rid of via active control. That is why system designers always try to make sure that these types of resonances are outside the area of interest. This means that the first natural frequency is typically designed roughly five times above the bandwidth. Hence, the control system is not affected in the lower frequency range. Vibrations caused by disturbances do occur, but the effect is not limiting performance.

If the demands for accuracy increase, however, designers using the traditional approach will be forced to achieve higher natural frequencies within the design. ‘The demands are increasing,’ says program manager Adrian Rankers of Mechatronics Academy. ‘That will come to an end, because it is not manufacturable anymore.’

Aversion

The traditional approach was sufficient for high tech system designers for many years. But in their search for increasing precision, all high-end system suppliers are now looking at the possibilities of implementing passive damping. Vermeulen: ‘I dare to say that it is becoming standard in the high tech systems industry. Not everyone is familiar with it, but it is expanding.’ Verbaan: ‘The big players such as ASML, Philips, TNO and ThermoFisher have the time to develop their knowledge and conduct research.’

Vermeulen: `Damping means that you deviate from the linear elastic behaviour of materials as defined by Hooke’s law. This is because the material converts part of the energy into heat. If you plot force against elongation in a graph, the dissipation is expressed in the hysteresis loop. The surface of this loop is proportional to the dissipated energy: the damping that you can provide to the structure.’In addition, stiffness and damping properties of rubber are temperature- and frequency-dependent (for specialists: linear viscoelastic models can be used for rubbers). As a result, these types of damping materials have been avoided for a long time: a system can have different states under the same load conditions. Vermeulen: ‘That means uncertainty in position.’ Precision engineers have an aversion to this. ‘With damping you deviate from the linear relationship. You pass through a hysteresis loop when the force increases and decreases again, and you don’t know exactly how since not all the forces that affect the system are exactly known. Often there are disturbances from the outside and then you can end up in a position that was not predicted beforehand. We have actually sought to avoid that uncertainty for a long time. As a result, everyone in the high tech systemssector has avoided damping and has designed things traditionally using masses and springs. But at a given moment, the possibilities come to an end.’

Venom

The venom, however, is in the above mentioned hysteresis loop. It’s more complicated to predict behaviour correctly, because the system can be found in different states as mentioned. This means that operating and controlling is complex in environments where floor vibrations and small variations in air pressure or temperature cause major disruptions. A soft exhalation over a wafer stage already provides a standing wave with an amplitude of several tens of nanometers while the stages need to be controlled at sub-nanometer level.Over the last few decades, the pursuit of the holy grail of completely predictable behaviour of guide ways has been expressed in the avoidance of friction as much as possible – also providing energy dissipation, hence damping. ‘In many applications, Coulomb friction is not desired,’ Vermeulen says. ‘Also, rRolling elements don’t work in every situation. That is why air bearings are popular. They hardly have any friction.’IBM already used air bearings in its hard drives in 1961. Lithographic equipment developed in the Sixties and Seventies at the Philips Physics Laboratory were equipped with virtually frictionless oil bearings, and use air bearing technology in multiple systems these days. . Vermeulen: ‘With the classical box of tricks to design frictionless guide ways, avoiding play, and applying high-stiffness springs with limited mass, we were able to make the behaviour predictable for a long time. But for nanometer applications and beyond, this is no longer sufficient.’

Wobbly pizza disk

Until recently, the classic approach was fine for designing motion stages for wafer steppers and –scanners. By using structural metals and ceramics, such a stage can be made lightweight and stiff. The natural frequencies are high enough not to be limiting for high-bandwidth control. However, the requirement for subnanometer precision make the introduction of more rigorous steps necessary.

'At the nanometer level it is as if you have to keep a wobbly pizza disk quite with your hands.'

Verbaan, during his PhD, investigated the influence of passive damping on a positioning system for 450 millimetre wafers. Such a stage has outer dimensions of 600 mm squared. ‘At the nanometer level it is as if you have to keep a wobbly pizza disk quite with your hands,’ says Verbaan. He compared various materials, , and investigated and optimized with finite element analyses the influence of mass distributions on performance.

Such a large system is susceptible to multiple resonance frequencies. To be able to control the stage accurately, these resonances must be suppressed. ‘For one frequency it is clear how that is done, and you can also put that into a simple model. But if you have multiple resonance peaks across a broad frequency band, that is virtually impossible. Then you get a model that is too complex to handle.’

That is exactly what engineers encounter in practice. The first ‘hurdle’ that limits system performance is the first natural frequency, the frequency at which an object starts to vibrate violently when the frequency is increased. The traditional approach is to try to increase this frequency. If the means for this are exhausted, attenuation can help to suppress the resonance amplitudes. The first eigenfrequency of a square wafer table is, for example, the torsion mode, for which two pairs of opposite corners move in phase. But at higher frequencies everything starts to rattle, due to the numerous parts and components that are attached to the table such as connectors and sensors. ’Multiple small masses that vibrate at kilohertz. They will ultimately determine the dynamic behaviour. You are not able to solve this via active filtering in the control system because there so many of them. With passive damping, however, you can solve all of that,’ says Vermeulen.

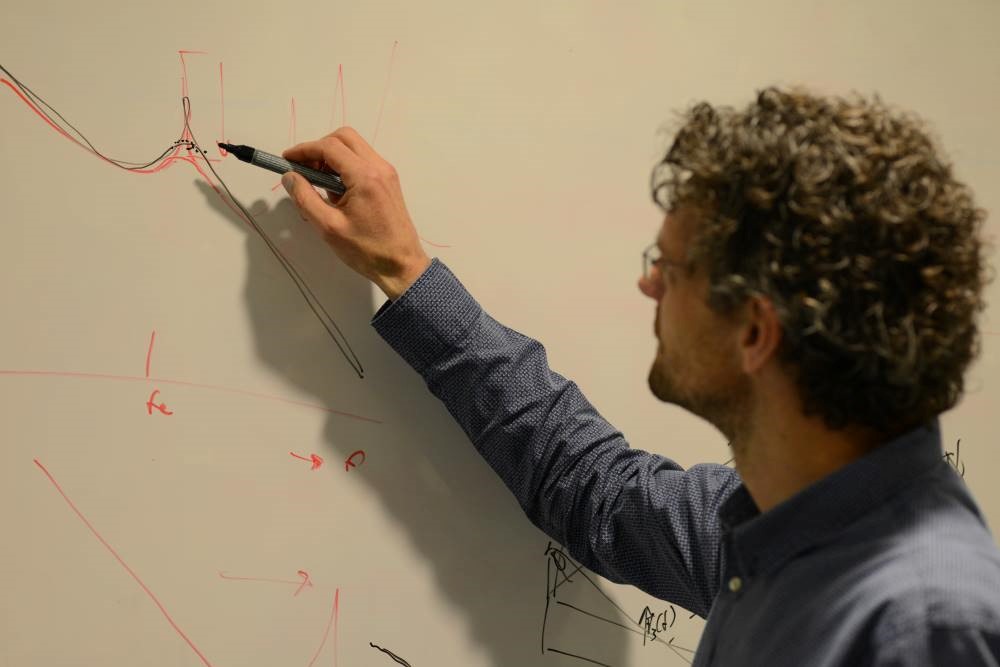

Hans Vermeulen shows how damping can reduce a resonance peak on a graph.

Hans Vermeulen shows how damping can reduce a resonance peak on a graph.

Verbaan: What helps is that damping materials such as rubbers and liquids and the dampers you design with these materials, typically behave very suitable at those high frequencies, primarily because of the frequency-dependent material properties. At low frequencies, they behave like a low-stiffness spring, and therefore give in a little bit, but at higher frequencies, they become viscous.’ Vermeulen and Verbaan’s training course makes it clear that, although you can make the field of damping extremely difficult, there are also very good rules of thumb and several very useful design principles. Verbaan: ‘Our goal is to outline the entire pallet of options and ensure that students attending the course can get to a solution using the right approach. You can let modern computers calculate for days or even for weeks, but then you have to be a real specialist. We want to provide the course participants with various possibilities for applying damping. They are taught the backgrounds of modelling, and also the simple approach to the problem so that they can apply damping correctly. ‘

‘Potential students are people with a design principles background on the one hand,’ says Rankers. ‘They want to apply damping in practice. On the other hand, system architects will also be interested, so that they are aware of the possibilities that damping can offer.’

Kees Verbaan draws a motion training stage that needs to be kept steady in a vertical position. All kind of forces act on such a table, varying from horizontal motors to accelerate, to vertical actuators that keep the wafer on the table at the correct height. At the first vibration mode, the opposite corners move up or down simultaneously, while the other corners move in the other direction. The result can be in the order of tens of nanometers, while the stage requires subnanometer position control.

Vermeulen and Verbaan underline that passive damping is not a ‘miracle oil’. An integral design approach is indispensable. ‘I have heard engineers saying: leave that mistake in for now, we’ll solve it later on with controls,’ says Verbaan. He says that people sometimes come to him with systems that don’t achieve the desired performance and ask him if they can use passive damping to fix it. Verbaan: ‘Sometimes, this is dealt withtoo easily. You cannot simply forget the basicss of sound mechanical design. It all starts with light-weight and stiff design which indisputably remains necessary, also for proper functioning of damping. The pallet of options is getting bigger, but damping is not a replacement.’In the course ‘Passive damping for high tech systems’, Verbaan and Vermeulen will explain multiple damping mechanisms in detail, such as material damping, tuned mass and robust mass damping, constrained layer damping, and Eddy current damping. Starting with damping implementations in other application areas, such as civil engineering and automotive, the focus is on design, modelling and implementation of passive damping in high-tech systems. Stan van der Meulen, co-trainer of the course, will focus on the application of viscoelastic damping in a semiconductor wafer stage.

This article is written by René Raaijmakers, tech editor of High-Tech Systems.

Recommendation by former participants

By the end of the training participants are asked to fill out an evaluation form. To the question: 'Would you recommend this training to others?' they responded with a 9.2 out of 10.