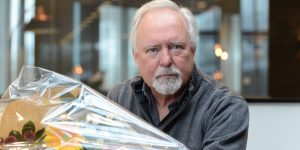

As a project leader, you have to be clear about your personal boundaries, says Wilhelm Claussen. Bringing with him experience in the semicon, automotive and special equipment industries, he’s starting as a trainer in project leadership at High Tech Institute. In this interview, Claussen talks about what makes a project leader and the dos and don’ts.

“With the right attitude, the right focus, the right spin in the right team, you can do pretty much anything, regardless of the cultural backgrounds of the people in your team.” Wilhelm Claussen raises the subject when asked about what influences development projects. According to him, the most important component is leadership. The term keeps popping up in our conversation. Claussen himself has plenty of experience in this field, having led tech development projects throughout his whole career in automotive, semicon and special equipment.

To kick off with the basics, Claussen underlines that he likes to separate project management from project leadership. “Project management is administration. It builds an environment for the project execution. The leadership part is about the people. It gives them a focus, the right pace and the right goal. To phrase it differently: bad project management with good project leadership may still prevail and give good results. Good management with bad leadership will result in a well-documented disaster.”

In the same vein, Claussen argues that the success of a project isn’t dependent on the chosen methodology – Prince2, waterfall, Agile or whatever. “The essence of success in projects is leadership, recognizing and sensing ahead of time if something is missing or looking strange.”

Trainer Wilhelm Claussen. Photo by Fotogen Fotostudio.

Flawless execution

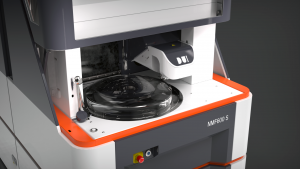

Claussen started his career in the mid-nineties in the Dresden wafer fab for DRAM memory chips of Siemens Semiconductors. “That might sound boring and traditional, but at that point in time, I experienced an environment with a real startup mentality. Siemens had almost missed the train in the microelectronics race and got a last chance to succeed.”

By the time the chip activities were spun out as Infineon in 1999, Claussen was ramping up wafer fabs around the world. “Basically, we transferred process technology from Dresden to fabs in the US, China and Taiwan.”

The big challenge was to flawlessly copy technology while it was still in development. “It was highly dynamic and had to be done with an extremely high pace. Especially in the DRAM business speed matters. Every month of delay translated directly into lower margins. The key task was to establish a robust but flexible project structure enabling the transfer of a manufacturing process of six hundred individual steps and make it work at a different site thousands of kilometers away. All the while, the process itself was still in development. That meant we had to be flexible for adaptations that were coming out of Dresden with respect to recipes, tools, sequence changes and all these things while being crisp and clear on the verification of the results on our product.”

Asked about the importance of a flawless project execution here, Claussen answers: “It’s really pretty simple. If you do anything wrong, the chip is dead. If you miss even a detail in one of your six hundred process steps, the result is very expensive scrap. We were transferring the processes to running foreign factories. There, we had to deal with different rule sets, different toolsets, different languages and, last but not least, different mindsets of the engineers.”

Later in his career, Claussen worked in the automotive industry and for special equipment companies like ASML and Roth & Rau (now Meyer Burger).

Outside view

Talking about the dos and don’ts in project leadership, Claussen dishes up four focal points. The first: never lose the main line. “In two minutes, you have to be able to explain the main steps and how you want to achieve the goals. The moment you realize you can’t, you need to rethink your strategy. Funny enough, I also do that in daily life sometimes. Just to check whether I can still cover it all. Once I recognize that I’m no longer able to summarize my project in two minutes, my alarm bells go off and I basically start to rethink my project. Otherwise, complexity will kill you. You’ll start to make mistakes, overlook things and at the end of the day, you’re exhausted and your products are dead.”

The second pitfall is ticking off boxes blindly. “Check, double-check and check again. Make sure you’re aware of the real project progress.” Claussen explains that this is all about creating an unbiased and independent outside view of the project. “Because you have to recognize that the moment you’re following a certain sequence or a manner of asking about the project progress, the system will start to bend to satisfy your request.”

Claussen developed his own methods to avoid this. “I frequently force myself to change the way I look at the progress of the project. And in doing so, I’m able to challenge the way the team reports progress. I do this to understand whether the people are actually delivering in time and if the reports are reasonably correct.”

“People in an automotive company could be rewarded for mounting wheels on cars because, in this company, this should be the last thing you do in manufacturing,” Claussen illustrates. “If your metric of project success is based on mounting four wheels on every car, you create an intrinsic opportunity for people to adapt to the metric rather than to the real progress by mounting wheels to even unfinished cars. This is normal human behavior and as a project leader, you constantly need to prevent these kinds of distortions. If you publish a reporting request, people will naturally try to look good in this reporting. And they’ll always report in the way that was successful last time. So you have to avoid that because you want to make sure that no one is ticking off boxes blindly and that people are reporting the real progress that they’ve made.”

Claussen’s third point is also a don’t: never delay required decisions, as hard and as painful as they might be to take and to communicate. “Naturally, you can expect headwinds and hiccups there. This is what real leadership is about. You should do this early and intelligently. Because this is a delicate subject, which can also seriously limit your career if you do this wrong. Nevertheless, it’s extremely important to act early after you’ve become aware. With an early decision and an early maneuver, you can maintain the legroom to counteract.”

His fourth and last advice: never take no news for good news. “The fact that you don’t hear anything from a certain project part doesn’t mean that they’re making progress. De-commitment is always silent. Later, it will come to haunt you for sure. It’s actually a little brother of the third rule because the persons not communicating their problem are basically avoiding the decision to communicate. As a leader, you need to recognize this. You have to understand: wait a minute. These guys haven’t talked to me for the last two weeks. Why is that? There can be a very simple reason. The person making the report might have had a personal problem, but there might also be a big hiccup they’re reluctant to talk about.”

Did you ever arrive at the point where you couldn’t defend your project anymore?

“Sure. And at that point, you have only two options. First, reshape your project, approach your sponsors and stakeholders and make sure that you get a new commitment to what you’re trying to change. If that doesn’t work, the second option comes into play: you have to give back your assignment and leave. This is one of the few things Donald Trump was correct in: you always have to be prepared to walk away from the table. Otherwise, you’ll become a victim. Becoming a victim is one of the traps I’ve seen many project leaders fall into – including me.”

It’s rather big trap.

“Yes, and it can lead to a lot of frustration.”

Once again: you have to have the guts to walk away?

“Yes. You won’t do that easily, but it’s very important for your personal well-being. You have to know your limits and need to communicate that to your stakeholders: that’s the red line that they mustn’t cross.”

Claussen gives an example from the time he worked in a company that developed special machines for the solar industry. Located in Korea, he was running the projects for the Indian and Asian branches. “That in itself was already quite a lot of work. All of a sudden, I received a call to also rescue a project they had running in Spain. I told them: because you have no one else to fix it right now, I’ll do this for three months, but not longer. Apart from traveling to Shanghai, Incheon and Hyderabad, I started to routinely fly to Madrid. After six weeks, I noticed that my management hadn’t taken any steps to mitigate the situation. They simply hadn’t followed up on their part of the deal and so I reminded them: I’ll do this for another six weeks and if you don’t change the situation, I’ll leave. Guess what happened? In the remaining time, they still didn’t do anything. So I left.”

Were they surprised?

“They sure were. The message I want to convey is that you have to protect yourself, and you need to be clear about what your red lines are. You have to communicate these red lines to the stakeholders and participants in the project so that they can act on them. Of course, I felt a little bit like a traitor walking away from my onsite team, as we were a good crew. Nevertheless, it was the right decision.”

Are these situations not the very nature of being a project leader?

“These situations are common in many projects. And that’s exactly why it’s so important for project managers to master them constructively. To do that, you need a certain mindset and preparedness. As a project manager or project leader, you constantly feel pressured to be faster, use fewer resources, be cheaper, get to market sooner. However, if you’re clear about your limits and constraints, your chances increase of getting across to people on the other side of the table what commitment means to a project. Commitment basically means signaling your agreement to follow the path you’ve laid out to achieve the project’s goal – nothing more, nothing less. When people’s expectations of you as the project manager become too strange, too weird and too abrasive, you have to cross the line and say, ‘Thanks, but no thanks.’”

“Being at this crossing point, it’s very helpful to realize, engagement is not a one-way subject. It’s kind of a two-way performance contract. Your sponsors can’t arbitrarily change the scope or any other agreed-upon part of the project and expect you to blindly follow. If the rules agreed upon by you and your stakeholders or project sponsors are violated, there must be consequences. If you don’t take immediate action on those violations, they’ll be committed again the next Monday.”

Claussen stresses that this has nothing to do with running away from or avoiding responsibility. “Nor is it about refusing to change. I’m talking about a serious violation of the agreed-upon set of rules by the people who gave you your marching orders without renegotiating or adjusting. And that’s where you have to be clear about where your boundaries are.”

Is staying true to yourself more important than your career?

“That’s a question that everyone has to answer for themselves. I think what’s important is that you know your own red lines and that others know that you take them seriously. No matter how powerful the stakeholders and project sponsors look, they need the project manager to get something done. So you need to be clear at the outset how much you’re committing and how much you’ll deliver, and you also need to hold the other ‘contractors’ accountable for delivering on their promises.”

This article is written by René Raaijmakers, tech editor of Bits&Chips.

Recommendation by former participants

By the end of the training participants are asked to fill out an evaluation form. To the question: 'Would you recommend this training to others?' they responded with a 9.3 out of 10.