Deep in the clutches of the COVID-19 pandemic, the first half 2020 has been interesting, to say the least. But as the Netherlands, and the world, tries to grapple with the novel coronavirus, High Tech Institute and training location partner BCN are working diligently to get back to business as usual. At least, as much as possible.

It is safe to say that the coronavirus has changed life as we know it. Zoom, Skype and Teams meetings have become the standard as large numbers of people work from home and avoid groups and gatherings. Now, as the government starts to ease the pandemic measures and looks to jump-start the economy, businesses are walking a tight rope full of safety protocols in an effort to get back to work – albeit, not exactly back to normal. One such company that has traveled this path is Business Centre Netherlands (BCN), which offers multifunctional locations for business events, meetings, testing and various training sessions.

BCN should be recognizable to participants from High Tech Institute’s technical and professional training courses, as the Eindhoven location is home to the vast majority of High Tech Institute’s trainings. However, when the coronavirus struck and group meetings were banned, it immediately threw a wrench in the plans for the 2020 training calendar.

“On 16 March, we were forced to close our doors for 11 weeks,” explains Ton ten Haaf, Operational Manager of BCN. “We reopened in early June, but as there was some uncertainty about what to expect, and because we were only able to welcome a maximum of 30 guests per day in the beginning, we shifted to accommodate the needs of our customers and focused also on virtual classrooms rather than physical. Right now, however, our main focus is planning and preparing to safely get people back in the physical setting, as we expect numbers to increase in September and after.”

Ton ten Haaf, operational manager BCN Eindhoven.

New normal

If you’ve been anywhere over the last few months, you’ve probably noticed businesses taking new precautions to limit potential virus spreading. And as the world tries to find some sense of normalcy, BCN has been working to create a safer ‘new normal’. “As soon as we had to close our doors in March, we began an 11-week period of intense planning and communicating with our customers. Immediately we started to devise several protocols aimed at keeping people as safe as possible once they returned,” describes Jenny Rennenberg, account manager at BCN.

“It already starts during the reservation process, well before anyone arrives. We communicate with our customers to determine the specifics of numbers and needs, so we can make suitable accommodations – especially the 1.5 meters distancing. Another thing we do is inform all guests of the room number in advance, so they can report to the training rooms immediately, rather than lining up in the lobby.”

These won’t be the only differences visitors and training participants will notice when coming to BCN. “We’ve also split the entrance and exit routes. Normally, in and out traffic uses the same space, but now we have placed tape, arrows and signs to help guide visitors through different corridors and stairways to avoid contact,” says ten Haaf. “We encourage people to use the stairs, but if they need or prefer to use the elevator, we just ask that they use it one at a time, as the space is very narrow.”

Tape, arrows and signs help to guide visitors through different corridors and stairways to avoid contact.

In person and online

Another precaution that BCN has adopted is that the rooms are now set up in an “exam”-style design, with rows and columns of tables – each a minimum of 1.5 meters apart. “While we can still offer the intimacy of the u-shaped setup, keeping in line with the distancing measures of 1.5 meters, means capacity is a little lower. By utilizing the exam-style setup, we can accommodate more people. It really just comes down to the needs of the customer,” expresses Rennenberg. With BCN’s attention focused on health and safety, and the implementation of all the necessary precautions, there simply isn’t the same space as before. In all, the training center’s Eindhoven location can now accommodate only about 130 of its normal 280-person capacity.

“That’s a pretty big blow, in terms of what we can normally handle,” comments ten Haaf. “However, with the uncertainty of the virus, there are still some people that will feel uncomfortable traveling and attending in-person trainings. To better fit their needs, we work with our customers to organize meetings that can take place both here on location, as well as online in the virtual world, offering the best of both worlds. So, I’d say we’re actually doing quite well.” “Yes, and if there is a need for an event or training for larger numbers of people, we can use multiple rooms connected with TVs, and speakers or trainers can visit and broadcast from any of the rooms,” adds Rennenberg.

Filling up

Despite the difficulties of having to close for nearly three months, and the slow times brought on by summer vacation, BCN is looking to have a strong year – even on par with 2019. “We’ve already had a few in-person trainings resume, and the feedback we’re getting from our customers and attendees is very encouraging,” touts Rennenberg. “So far, comments have been very positive. We’re finding that most people really prefer the physical classes over virtual, and we’re hearing that visitors are happy to finally be back to doing such things on location again, especially with all the measures we’ve taken.”

Of course, that sentiment is very welcome and seems to be holding true. Since the broader easing of the national corona measures in early July, BCN’s customers have been calling nonstop. “One challenge we’ve had to work through is scheduling. Most of our customers book well in advance, even into next year,” highlights Rennenberg. “Now we’re getting a lot of calls from people that had to cancel during the shutdown, that now want to reschedule in the latter part of this year. That has taken quite some planning and scheduling adjustments, but so far, we think it’s going very well and we expect a strong finish to 2020.

This article is written by Collin Arocho, tech editor of Bits&Chips.

“In the future, we will be moving more and more towards end-to-end modeling,” says Stefan Bäumer, lecturer at High Tech Institute.

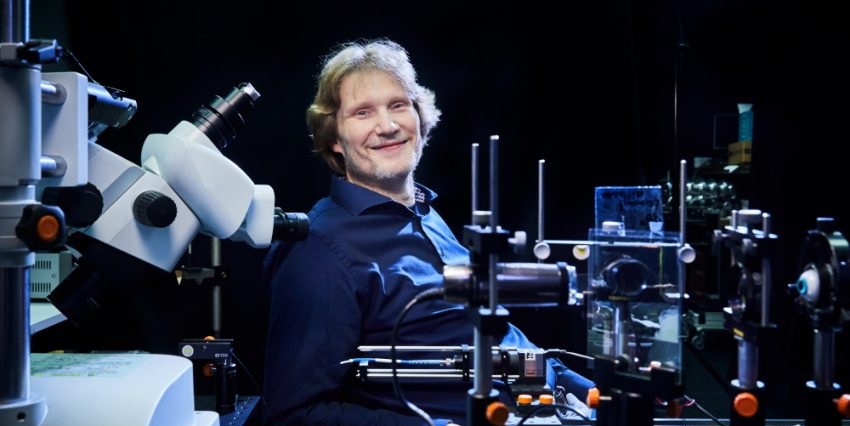

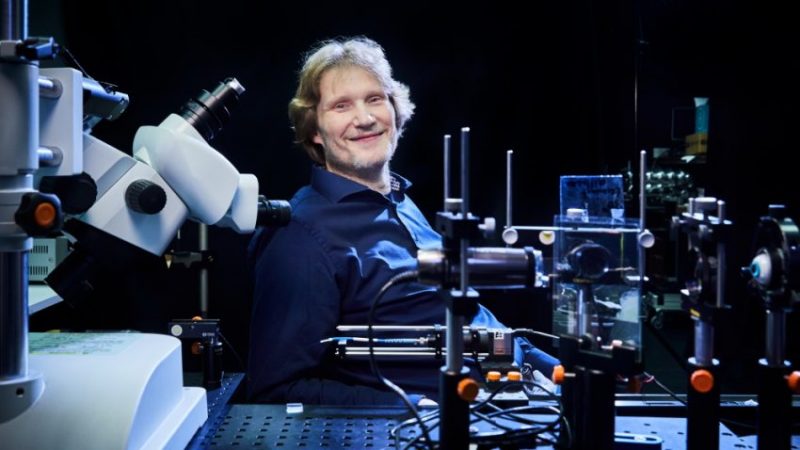

“In the future, we will be moving more and more towards end-to-end modeling,” says Stefan Bäumer, lecturer at High Tech Institute. Stefan Bäumer: “I would like to give my students a good basic optical knowledge, which enables them to make a good estimate of what is possible with optical systems. And, of course, also where the boundaries of feasibility lie'” Photo: TNO.

Stefan Bäumer: “I would like to give my students a good basic optical knowledge, which enables them to make a good estimate of what is possible with optical systems. And, of course, also where the boundaries of feasibility lie'” Photo: TNO.