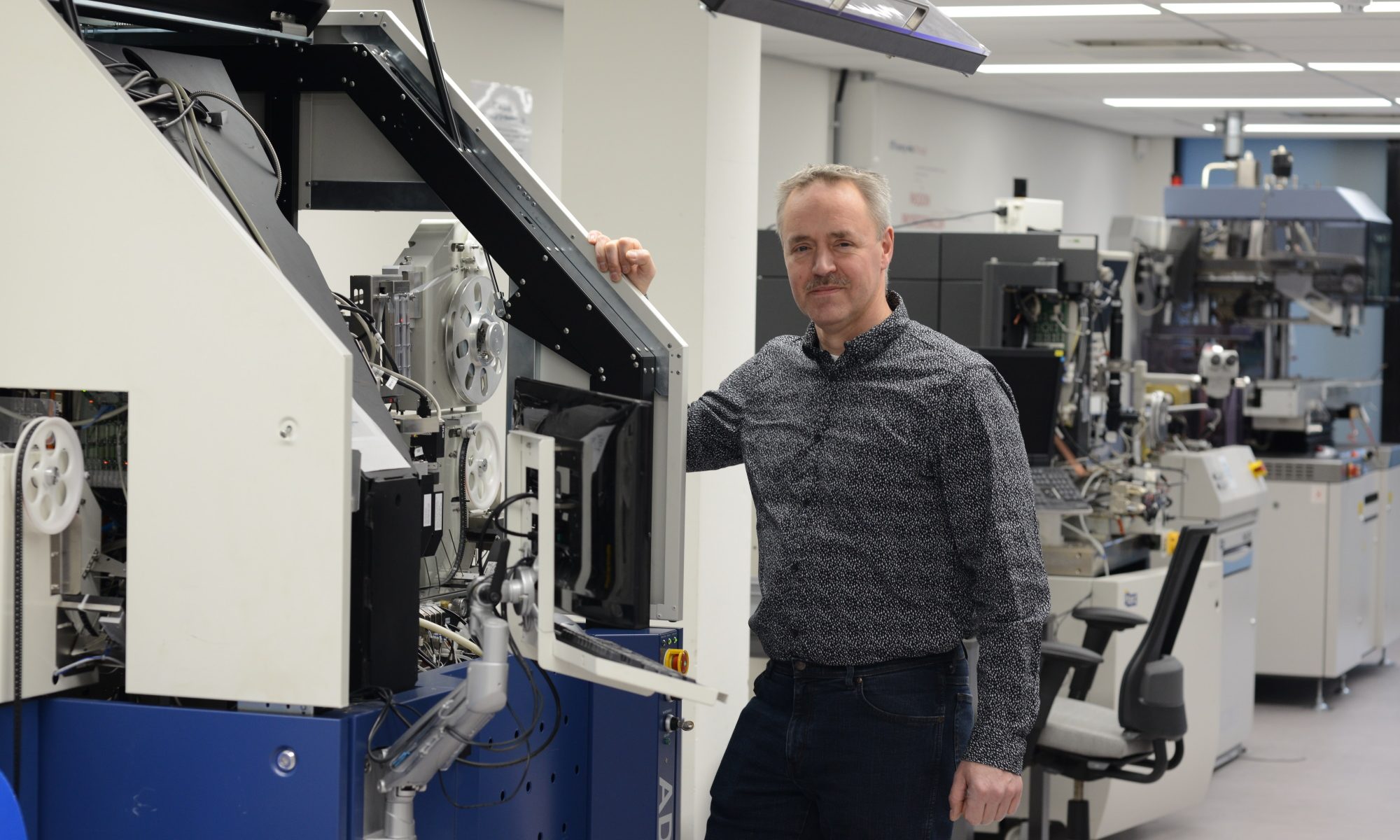

To better understand his customers’ technology and applications, Ralf Noijen, systems engineer at AAE, took the Applied Optics course at the High Tech Institute. “We like to take part in the discussions at a high level,” he says.

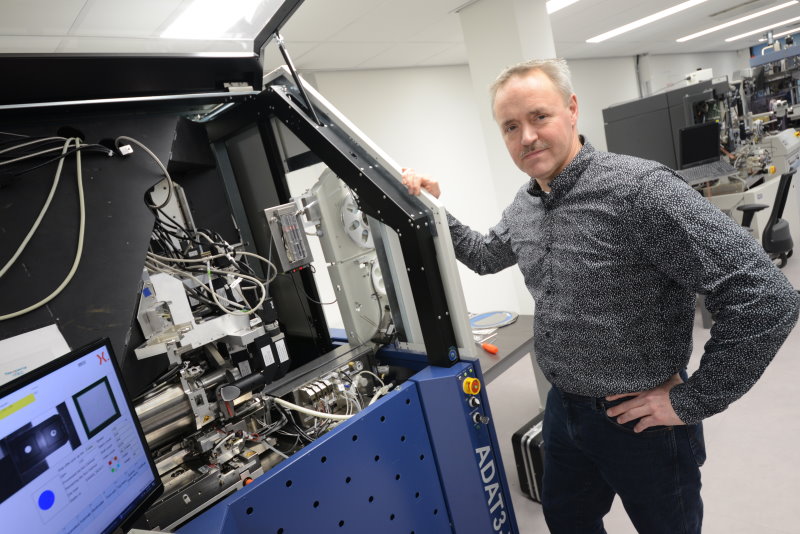

In Helmond, AAE produces the C-Trap for Amsterdam-based LUMICKS. With this instrument, researchers can investigate, among other things, the binding of proteins to DNA strands. Understanding this molecular interaction is important to clarify the mechanisms of specific diseases.

For that research, it is necessary to manipulate the DNA strands. To do so, they are connected at the ends to small polystyrene beads. That combination is then placed in a liquid in contact with labelled specific proteins. The C-Trap allows researchers to study DNA strands with bound proteins using optical techniques.

The instrument is able to manipulate the beads with laser beams. “You can think of it as optical tweezers,” Noijen explains. “The laser beams catch small beads of polystyrene flowing through a glass channel. Between two beads is a single strand of DNA containing proteins labelled with fluorescent substances. By pulling two beads apart with optical tweezers, the stiffness of the DNA strand can be measured and thus the influence of the bound proteins. Sub-pico-Newton forces can be measured with this system.”

The instrument mainly serves to research diseases such as cancer. “The main customers of these machines are universities and research institutes,” said Noijen.

Ralf Noijen: “Theoretical parts of the course were balanced with a healthy dose of experimentation.”

Small microscope with flowcell

Another project AAE is building for LUMICKS is the z-Movi platform. “That is basically a small microscope with a flowcell in which tumour cells can be grown,” says Noijen. “The microscope is used to study the binding between cancer cells and immune cells. Those cancer cells are brought into contact with the drug of a specific immunotherapy in the flowcell. On top of this flowcell, a piezo element is attached. The piezo element vibrates the fluid in the channel and creates a standing acoustic wave. The immune cells are attracted to the node in the standing wave. By increasing the amplitude, the attached immune cells release at some point, which tells us something about the strength of the binding. The Cell Avidity platform measures the moment of release optically. This gives us information about the binding and thus the effectiveness of immunotherapy.”

''Throughout the course, we learned about the latest updates in all the areas covered. We were taught by real experts.''

Understanding sensitivities

The great importance of optical phenomena prompted Noijen to take the Applied Optics course at the High Tech Institute, mainly as a basis for working with customers. Noijen: “At AAE, we focus on manufacturability, testability and assembly. But we like to think along in the development process so that we can take care of all aspects. Over the years, we already built up a lot of application knowledge and we oversee more and more parts of development. That is precisely why a course like this one comes in handy. Optics is very important in the LUMICKS systems. The better we understand their sensitivities, the better we can assess whether our proposals will work.” Noijen already had experience with training courses from the High Tech Institute. “When I saw the Applied Optics course description, I thought: ‘hey that fits in nicely with the platforms we build for LUMICKS.’”

Carving out time

The course was intensive, notes Noijen, totalling 13 half-day sessions over six months. In between, he did five homework assignments. That was tough, but Noijen is nevertheless positive about the experience. “I just found it very interesting, so I didn’t have much trouble taking the time out for it,” he laughs. “You have to schedule it, of course, because life is busy.”

On the structure and content: “It started with the basics of light, what is light? From there we went to modelling and when you can use it. Which aspects are important? For example, when can you use ray tracing? I liked the build-up from basics to applications. Then lighting and sensors were also covered. The last sessions went deeper into ASML’s lithography. I found that very insightful. I worked at ASML so the subject matter was not entirely new to me, but still there were many things that I saw for the first time. Throughout the course, we learned about the latest updates in all the areas covered. We were taught by real experts.”

The theoretical parts of the course were balanced with a healthy dose of experimentation. “It goes deep into theory, but then you start experimenting. When you experience how everything really works, the theory sticks better. You learn more easily when you’ve had something in your hands. That was the uniqueness of the course.”

''If I had done this course earlier, I would have been better able to spar with the opticians in previous projects''

Discussions

For Noijen, the optics course was especially important to build a better connection with his clients. Deeper technical knowledge allows him to better engage with experts and companies. “I think we can now participate at a higher level,” he states. “That’s really nice. You learn to speak the same language about a machine. If I had done this course earlier, I would have been better able to spar with the opticians in previous projects. This also helps AAE by the way. Our primary proposition, especially for start-ups, is that we build their machines. But on top of that, you still have a competitive advantage if you can talk about the application at a high level. If you can show that you understand the sensitivities, that builds confidence.”

This article is written by Tom Cassauwers, freelancer for High-Tech Systems.

Recommendation by former participants

By the end of the training participants are asked to fill out an evaluation form. To the question: 'Would you recommend this training to others?' they responded with a 8.9 out of 10.

Here at Sioux, or anywhere else for that matter, not everyone has the aspiration to become a senior system architect,” says Duncan Stiphout. Photo by Bart van Overbeeke.

Here at Sioux, or anywhere else for that matter, not everyone has the aspiration to become a senior system architect,” says Duncan Stiphout. Photo by Bart van Overbeeke.