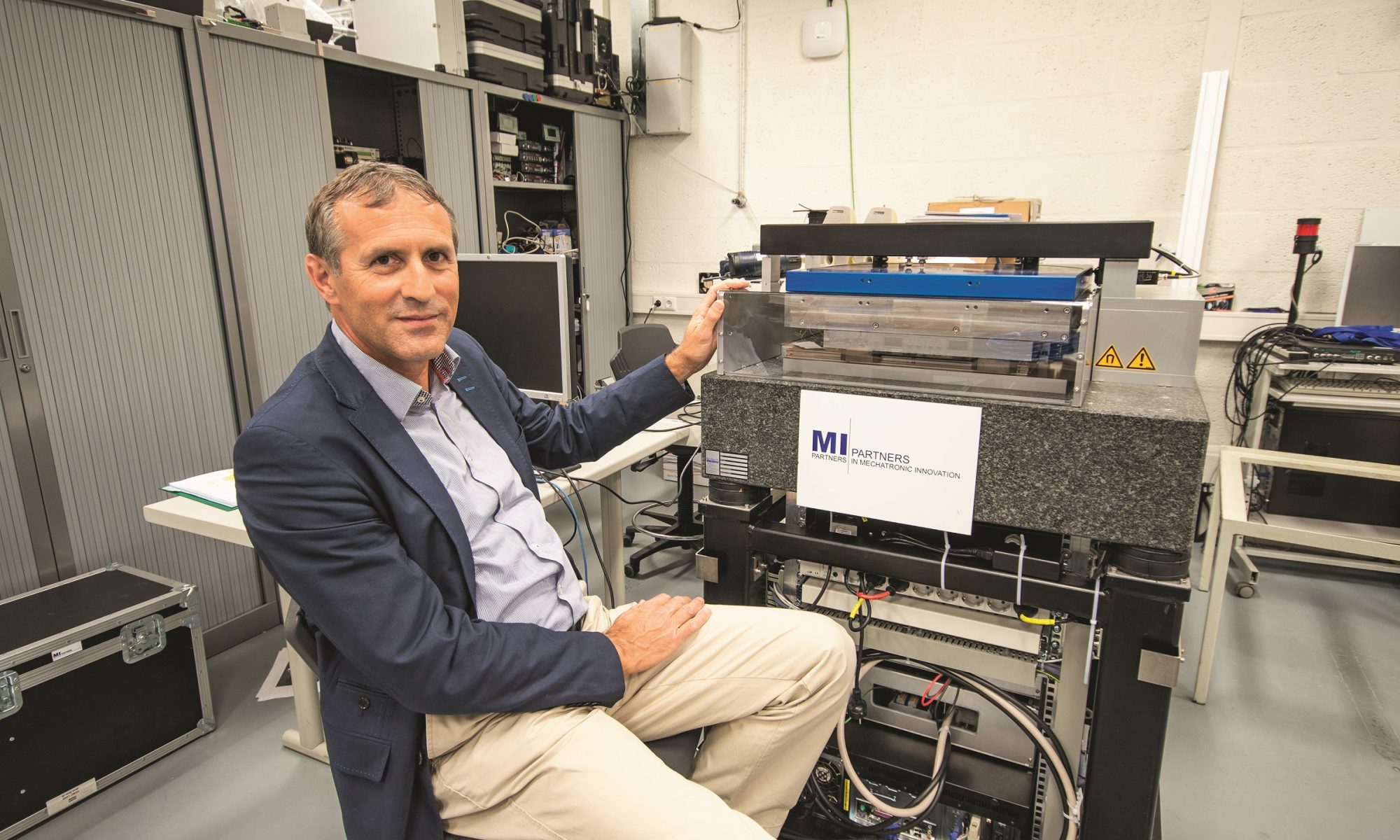

Huub Janssen from Janssen Precision Engineering is one of the former figureheads of the Design Principles for Precision Engineering training. His ambition was to spread know-how in the vein of Wim van der Hoek.

A longstanding wish of Huub Janssen of Janssen Precision Engineering has been fulfilled: he shared his knowledge in the same way that his mentor Wim van der Hoek did.

Janssen deems Van der Hoek ‘awe-inspiring.’ In the early 1980s, he was looking for a niche in which to spend his last university years at the Eindhoven University of Technology and came across a professional who worked mainly in precision mechanics. “Wim invited me to his monthly mornings. There he would put a large sheet of paper on the table and scribble down all kinds of problems. We would discuss them with a handful of students who each had their own graduation assignment and for two to three hours we would talk about progress and technical problems.’

Huub Janssen is the new figurehead of the Design Principles for Precision Engineering training course.

The main focus was on the content, the technical approach, the concept and how it is put into practice. ‘Everyone offered free solutions. One graduate would put down his problem and then five or six men would jump up to solve it in various ways. It was some game. That stimulation from Wim really appealed to me. I took to it like a fish to water. It goes without saying, I felt at home.’

In the ‘80’s, Janssen worked at ASML, made production equipment for LCDs at Philips in Heerlen, and then started an engineering firm dedicated to precision instrumentation. Education has always attracted him, but in recent decades entrepreneurship has taken priority. ‘Just like Van der Hoek, I have always enjoyed discussing technical problems with young people. I also do that when coaching my employees,’ says Janssen.

Now that employees have taken over part of his duties, his thoughts have automatically turned to knowledge transfer. When approached by Jan van Eijk and Adrian Rankers of the Mechatronics Academy, partner of High Tech Institute, Janssen didn’t have to think twice.

Limburg’s flan

We are talking in the very space that Huub Janssen named after his great inspiration, Wim van der Hoek. Over Limburgs flan and coffee, the precision engineering entrepreneur raises a subject that engineers often bring up in conversation: the passion he already had for technology in his youth.

In Janssen Precision Engineering’s new meeting room, completely surrounded by glass. Huub Janssen named the space after his mentor.

During his high school years Janssen photographed birds. His challenge was to capture them in flight. He didn’t want to sit behind the camera all day long, so he came up with a solution. In a nesting box, he set up a Praktica – the SLR camera that still fitted a more or less within his budget – and put together a shutter mechanism with a light beam and photodetector. ‘Everything was arranged so that the Praktica shutter closed at the precise moment that the bird flew through the beam. An electric solenoid triggered the self-timer. Not with a normal motor, because it had to be bam! Done.’

He received his entrepreneurial spirit from home. His parents had a fruit company and his father often built machines himself, such as a machine to sort apples. During his last years at university, Huub devised a measuring scale which made it easier to fill fruit trays with a specific weight. Not ordinary scales because with those you would need to calculate back and forth and Janssen wanted to avoid that. ‘You could buy those kinds of scales for three thousand guilders, but that was a lot of money back then. I wanted something that would enable you to see in one go whether you had to add or take away a few apples. I was always thinking about things like that.’

He solved it with leaf springs, electronics and an optical sensor. ‘There were all kinds of Van der Hoek design principles in it,’ he laughs, referring to the professor whose Monday morning sessions he sat in on that time.

During his final years at university, Janssen developed an instrument that could map out wear and tear in fillings and molars. ‘Interferometry and optics were part of the solution. I had to position in six degrees of freedom within fractions of a micrometer, and I could completely break loose with new ideas. Moreover, I also had a real customer so it had to work eventually.’

Huub Janssen with the piëzo-knob, a component on which he has a patent; a revolutionary concept based on piëzo elements and a rotating mass, steps of 5 nanometres can be made.

After graduating in the eighties, Janssen worked at ASML on the first PAS2500 wafer stepper. ‘I had learned a lot from Van der Hoek, but at ASML I have been able to see where things can go wrong. With Van der Hoek you learn to design something statically determined. For example, you get stability with three support points. But not everyone is happy with a three-legged table. At ASML I learnt to understand when to apply specific design principles and when not to.’

For the PAS2500, they had initially developed a new interferometer to measure the position of the stage in directions x and y. ‘We did this completely in accordance with the Van der Hoek design principles, with elastic elements and so on. There was no hysterisis, but everything kept vibrating. There, I learnt that you cannot always apply Van der Hoek’s design principles in any situation. You have to know when you can and when you can’t,’ explains Janssen.

After ASML, he joined Philips in Heerlen, where he developed production equipment for LCDs. A few years later he started his own engineering office. ‘During my final university years, I also worked for a real customer with a real technical problem, including the demand for hardware. That was just my thing.’

In 2010 Huub Janssen received the Rien Koster prize in recognition of the high level at which he practices precision technology in his company Janssen Precision Engineering (JPE). In addition to the large amount of advanced work done for clients, the jury also emphasised Janssens’s attention to the coaching and training of his employees. JPE has since recorded thirty patents for its inventions.

Within JPE, more than ten years ago, Janssen started collecting and documenting technical principles and solutions. Initially for his employees, but also for the outside world. Whenever Janssen or his colleagues delve into something or have to come up with a technical solution, they record it. ‘We always have to figure something out or look it up again. How did that technical calculation go again? I thought: let’s do it properly once, and then the next time employees need it, they will also benefit from it. I started documenting the cases on one A4 sheet. ‘Everything is divided into categories such as ‘engineering fundamentals,’ ‘construction fundamentals,’ ‘dynamics and control’ and ‘construction design & examples.’

You have to invest time in it, ‘but then you also have something,’ says Janssen. ‘The technical problem, all the formulas that matter, all have to fit on that sheet of A4. That means only the essential information. In the meantime, it totals about fifty sheets of A4. Janssen thought that the information also had marketing value and started to publish it. That is how the precision point came about, a page on the Janssen Precision website where everything is accessible. ‘Even a professor at MIT mailed me to ask if he could use the knowledge in his lectures.’ Janssen also bundled the A4 cases in a handy booklet under Albert Einstein’s motto ‘never remember anything you can look up.’ He regularly receives orders from schools, competitors and customers.

Under Albert Einstein’s motto ‘never remember anything you can look up,’ Huub Janssen has documented precision cases. Each case fits on one sheet of A4. The knowledge is available at Precision Point on his website, and also available in print.

It is difficult to say whether the efforts also generate extra business. ‘We can, however, see that interested parties look at our core activities in high tech engineering and at our products after reading our precision point link.’

He said yes to Van Eijk and Rankers’ request to become the figurehead of the Design principles for precision engineering training course because education always attracted him. Much of the knowledge and experience in the design principles training course comes from the Wim van der Hoek ideology. ‘Just like Van der Hoek, I have always enjoyed discussing technical problems with young people. I also do that when coaching my employees,’ says Janssen.

For old students and colleagues, Van der Hoek can’t put a foot wrong. When they praised him at a party in honour of his 80th birthday, the Emeritus Professor responded: ‘I am praised in heaven in a shameful way.’

But after some thought, Janssen manages to dig up a criticism. ‘He liked to talk. He talked pretty quickly, so it was quite difficult for beginning university students, who still had to master the profession, to follow everything. You really had to pay attention, because a lot of information came flying at you in those few hours.’

Van der Hoek liked to talk, rapidly pointing in which direction to go, and he also had something to say. ‘He quickly came up with his own ideas about the path that solutions should take, and that was often astonishing.’

‘Thirty years ago, positioning at a micrometre was something from another planet.’

What was so special about Van der Hoek’s approach?

‘It has to do with the field. Thirty years ago, positioning at a micrometre was something from another planet. It is a field where you cannot simply apply normal functional elements such as bearings and gears. Even at this moment, it is still unexplored territory for many parties. Worldwide. Until the fifth year at university, we only learnt what other prospective engineers were learning: gears, drive shafts, v-belts and so on. But if you are going to position at a micrometre or a fraction thereof, then you can’t simply use those components. Then you get completely different solution directions and things such as reproducibility and avoiding backlash become important.’

You want to shape the design principles training in the spirit of Van der Hoek. What do you mean?

‘We are talking about design principles for precision engineering. That is the world of complex machines and instruments for the chip industry, astronomy and space travel. To position more accurately than a micrometre, you cannot simply use standard functional elements such as bearings. Then you come to elastic elements, no friction and those sort of things. After that it becomes exciting, because you are very close to physics.’

Janssen: ‘I can still remember that Van der Hoek asked his students to crawl in thought into a ball bearing.’

Manufacturers must recognise that they cannot buy standard parts from a catalogue. They have to think a bit further, analyse all the problems that may arise. Then you have to imagine things in your head, do ‘thought experiments’: where can things go wrong? If you can see that, the way to the solution is close. ‘I can still remember that Van der Hoek asked his students to crawl in thought into a ball bearing, to imagine the outer ring and inner ring with all the balls in between. We had to make ourselves so small that we were sitting between those spinning bullets. Then you see that the ball on one side is against the ring and on the other side has room to play. Next you see that a bullet isn’t completely round, it has indents and doesn’t turn well. If it is an indent of a micrometre then it means a micrometre of error. You don’t have to have much experience, but you do need a lot of imagination to be able to do thought experiments.’

What is specific about your contribution to the training?

‘The way solutions are reached is important. I don’t have a lot to do with formulas. Of course, they are needed, but calculating is the last ten percent of the job. Primarily, designers need to get a feel for the details. What should they pay attention to? How do they solve matters? You first need to know where things can go wrong and then come up with a good conceptual direction. I especially want to instil intuition. Calculation techniques will come after that.’

That’s why I want to introduce case studies. Van der Hoek did that in his Des Duivels prentenboek in which he published unsuccessful projects. ‘Participants thus get to work alone and in groups. Then we have a large group discussion. I don’t want a lecture, I prefer interaction.’

This article is written by René Raaijmakers, tech editor of High-Tech Systems.

Recommendation by former participants

By the end of the training, participants are asked to fill out an evaluation form. To the question: 'Would you recommend this training to others?' they responded with a 9.5 out of 10. Besides Huub Janssen, trainers include Dannis Brouwer (University of Twente), Piet van Rens (Settels Savenije), Kees Verbaan (NTS), Chris Werner and Roger Hamelinck (Entechna Engineering).

Huub Janssen is the new figurehead of the Design Principles training course. Like Piet van Rens, he comes from the school of thought of Professor Wim van der Hoek. The precision engineer honoured his mentor by naming the new meeting and demo room at Janssen Precision Engineering after the person who had inspired him, Wim van der Hoek.

Huub Janssen is the new figurehead of the Design Principles training course. Like Piet van Rens, he comes from the school of thought of Professor Wim van der Hoek. The precision engineer honoured his mentor by naming the new meeting and demo room at Janssen Precision Engineering after the person who had inspired him, Wim van der Hoek.