The hands-on course ‘Advanced feedforward control’ focusses on techniques to improve the performance of motion systems by advanced feedforward and learning control.

Our latest edition in March 2018 (fully booked) organised by dr. ir. Tom Oomen, with additional lecturers from Academia, including prof. dr. ir. Maarten Steinbuch, ir. Lennart Blanken, and ir. Robin de Rozario, as well as lecturers from industry, including dr. ir. Joost Bolder (ASML) and dr. ir. Sjirk Koekebakker (Océ), was a great success. With twelve participants from eight renowned companies from all over the world US 4x, Israel 2x, Germany 1x, Czech Republic 1x and The Netherlands 4x this edition had an overall score of 9/10. The majority of the participants were from industry, with a large range in variation of work experience, and one participant from academia. For the first time the training duration was extended to three days, which provided time for additional topics and more time for hands-on experiments.

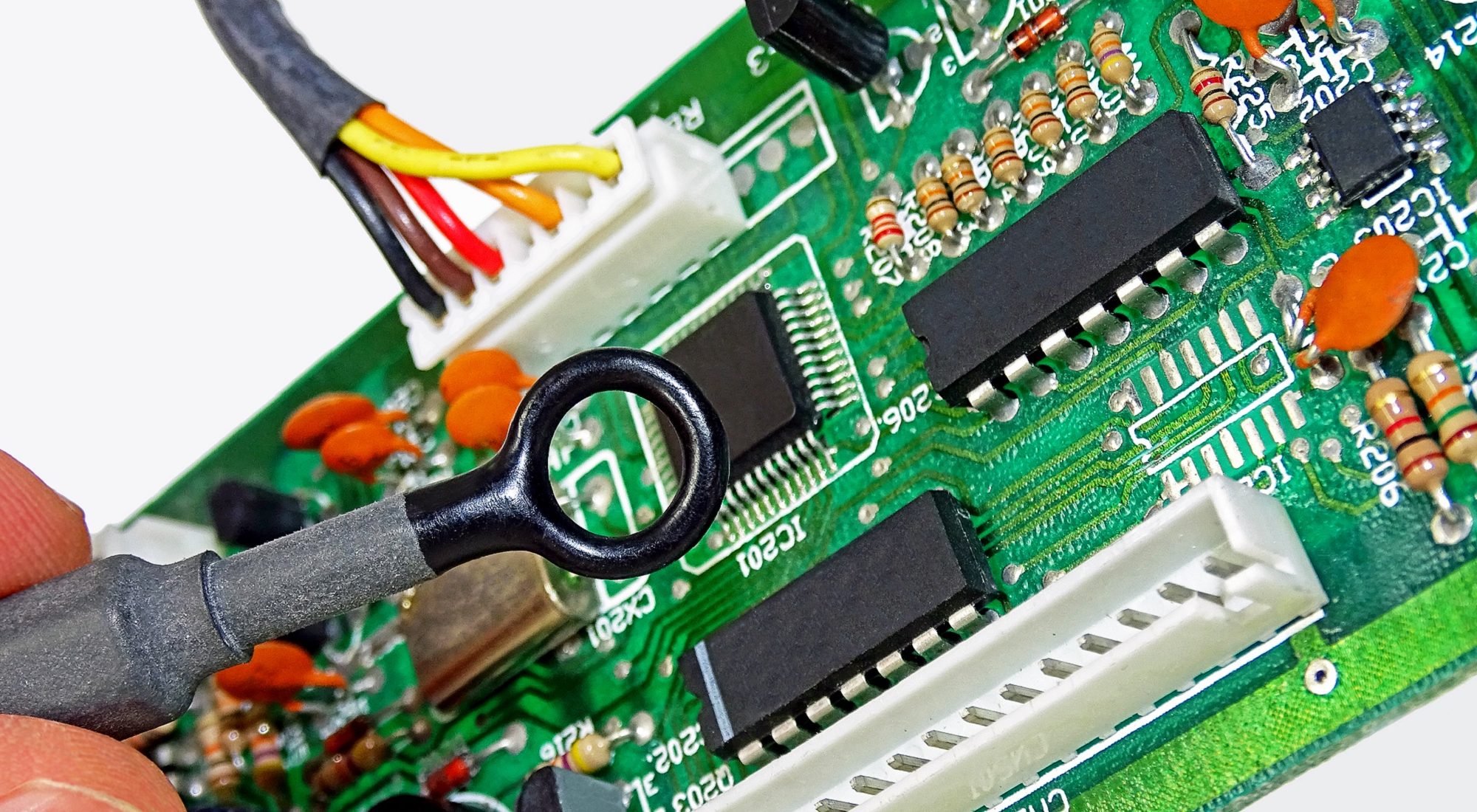

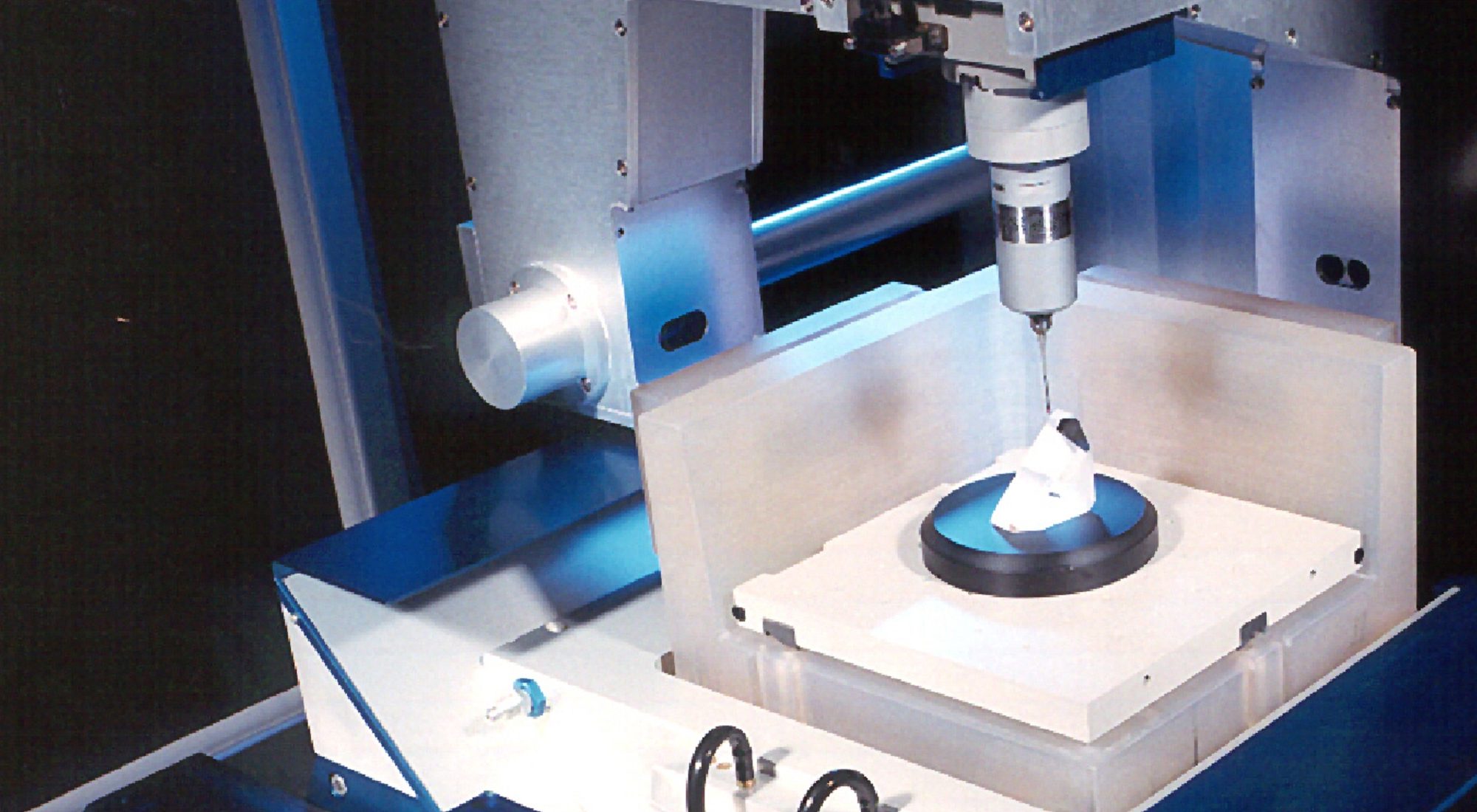

Already on day one, all participants managed to design a frequency domain Iterative Learning Control (ILC) algorithm and implement this successfully on a desktop printer. All participants also tried to tune a standard feedforward tuning, but even for the best tuned results, the ILC drastically outperformed the traditional approaches. The second day, the learning controller is adapted to a basic repetitive controller, enabling continuous operation of the printer setup.

The second half of the course contained several diverse topics, with speakers from both academia and industry. On the one hand, lifted ILC, which is more mathematically and academically oriented is investigated. On the other hand, the algorithms are tailored towards automated feedforward tuning, enabling the automatic tuning of complex feedforward filters, including input shapers. This topic is highly relevant for industrial applications with varying tasks, and attracted considerable interest from the participants. Furthermore, very recent, even unpublished research has been presented to avoid modelling steps in learning algorithms. All of these algorithms have been implemented successfully by the participants as well on the desktop printer setup. Finally, the course has been concluded by a presentation from an industrial expert on learning control in printing.

A few comments of the participants given at the end of the training are:

- “Great lecturers and great content!”

- “Very well prepared and lectured. Balanced mix of theory and applications.”

- “Excellent course, delivered enthusiastically and strikes the right balance between theory and experiments! Congrats!”

- “Excellent training! I enjoyed it very much and I’m looking forward to implementing some of the concepts learnt from this training!”

- “Very practical and useful, the explanation is easy to understand”

Interested in this course? Read the entire description of our ‘Advanced feedforward control’ training here and register in time since a limited number of seats are available!